The global demand for plastic waste reduction and more sustainable packaging solutions, coupled with health and safety concerns as a result of Proposition 65, have resulted in widespread initiatives to replace polystyrene - the favored material for Form-Fill-Seal processing - in food packaging applications.

With many brand owners making the commitment to transition packaging solutions out of PS by 2025 - and in some cases 2022 - the race is on to develop alternative material structures that result in a more sustainable solution, without sacrificing performance, barrier protection, or mechanical properties. Oh, and let's not forget - without adding cost or requiring significant capital expenditures to replace existing systems and processes.

Add up all of these requirements and sometimes it feels like an impossible task!

But what if a solution existed that maintained all of the positive attributes of current materials - processing, function, barrier protection, quality, and cost - but in the form of new formulations and technologies that resulted in a more sustainable product and offered a solution that did not require the replacement of billions of dollars of processor owned systems?

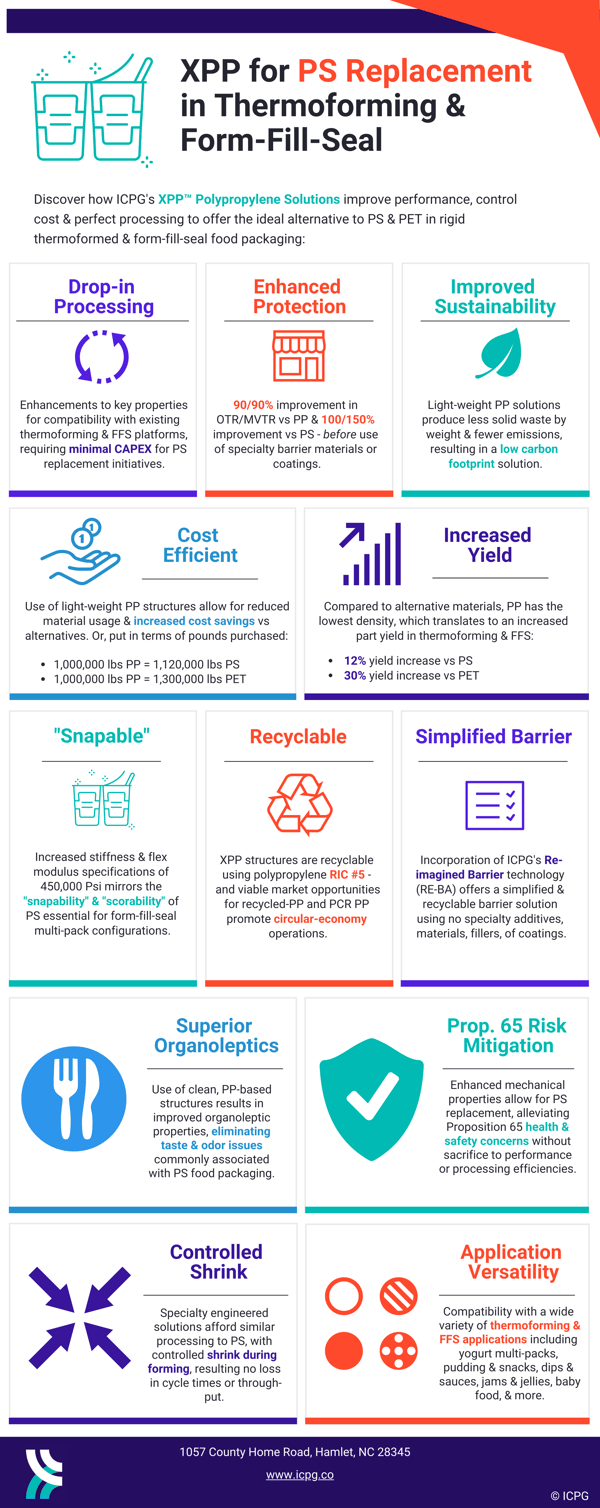

With ICPG's XPP™ Enhanced Barrier Polypropylene, we can now offer a solution that checks all of the boxes to provide the perfect PS replacement solution for form-fill-seal food packaging applications, from yogurt multi-packs, to single-serve creamers, to pudding cups, single-serve condiments & dips, shelf-stable beverages, and more.

Explore the infographic below to learn more about the attributes of ICPG's XPP Enhanced Barrier Polypropylene that make it the ideal PS replacement solution for form-fill-seal processes:

Interested in learning more about ICPG's materials and solutions?

-

- Check out our Industry Insights Blog

- Explore our market solutions

- Review our customizable extrusion capabilities

- Learn about our revolutionary visionX quality monitoring system